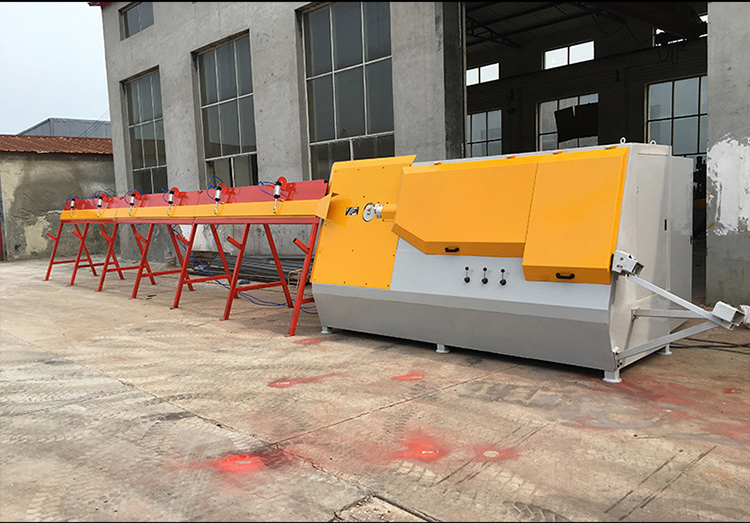

This equipment use Panasonic control system with touchscreen, could automatically accomplish processing of feeding, straighten, bending and cutting on rebars.

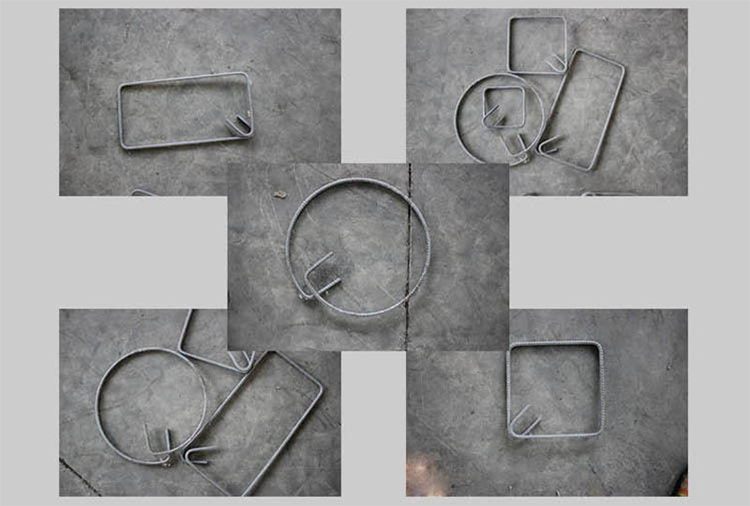

Max bending diameter of rebar is 12mm,widely used in construction industry and rebar manufacturing enterprise;

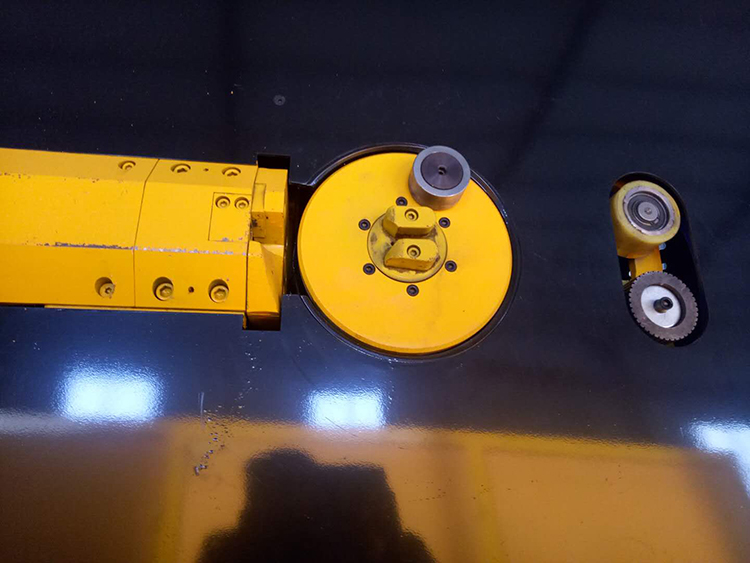

1, combine with horizontal and vertical straightening wheels, drive by imported servo motor, make sure best accuracy when straightening rebar.

2, bending spindle could rotating and telescope in high speed, could cut rebars very quick to get high bending precision.

3, large storage capacity can save many processing graphics,

4, Panasonic control system, Panasonic touchscreen, Inovance servo motor.

5, straightening, measure length, bending, shear at same time, processing in high efficiency.

Automat steel bar bending machine |

Processing range of a single steel | Level I round steel 4-12mm |

| Level III thread steel 6-12mm |

Processing range of double steels | Level I round steel 6-10mm |

| Level III thread steel 6-8mm |

Processing efficiency | 1440 pcs/hour |

Max. Bending angel | ±180° |

Max. Feeding speed | 2000mm/s |

Max. Bending speed | 1000 (°/s) |

Ground clearance of bending spindle | 1120mm |

Stirrup side length | 130--1800mm |

Average electric power consumption | 6kw/h |

Total capacity | 32.35kw |

Features:

1, automatic stirrups production equipment, at the same time with straightening function, a machine with two.

2, the use of intelligent control, processing a variety of sizes a variety of square, rectangular, diamond, polygon.

3, from the wire rod raw materials to stirrup products a molding, processing cold, hot-rolled high-strength wire rods.

4, high production efficiency, quite twenty to thirty workers.

5, equipment, strong, only one person operation, save a lot of labor.

6, save raw materials, in the work is continuous molding almost no steel material head loss.

7, covers an area of small, save the alignment work area and cutting work area, can operate in a narrow area.

8, equipment maintenance costs and energy costs are very low.

Contact detail

Eunice Jia

Whatsapp:+86 18331948815

Email:Eunice@hbxh-machinery.com