1. N95 mask machines are used for full-automatic folding mask production (typical models like N95 mask).

2. The working process of Minghui N95 Mask Machines are as follows: The multi-layer non-woven fabric rolls are subjected to compound roll welding after feeding. Nasal lines are welded after unrolling and cutting. Two rolls of rubber band are welded after automatically unrolling and cutting to designated length. Then masks are folded in half. After ultrasonic welding and fusion, the masks are rolling-cut and formed. Finally, we get finished N95 masks.

3. The masks have great filtration effect, perfectly fit face of people and are comfortable to wear without causing any pressure . The masks can be applied to various fields, like medical, electronics, mining, construction, etc.

4. Mask Machine uses PLC, touch screen control and the main conveyor adopts unidirectional motor transmission, which can achieve precise movement, stable control and adjustable speed.

1.1 Name of equipment: KN95 mask machine

1.2 Type of equipment :2021- KN95

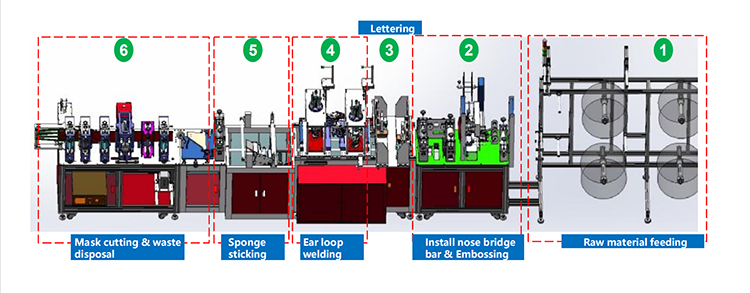

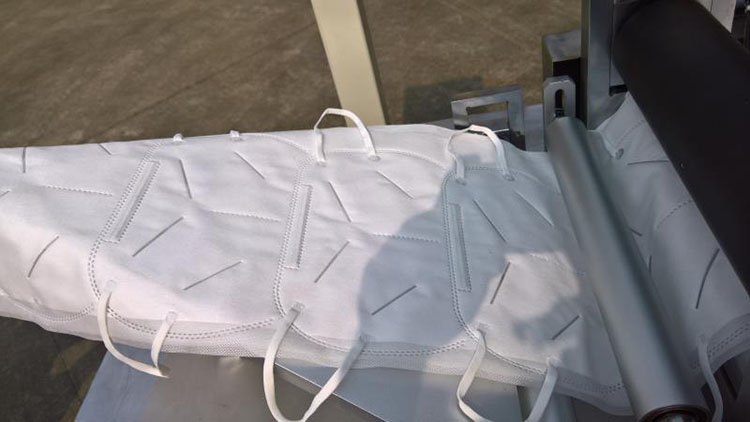

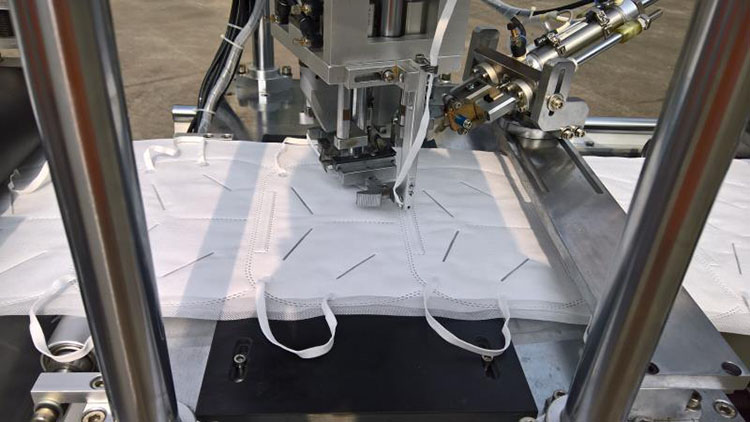

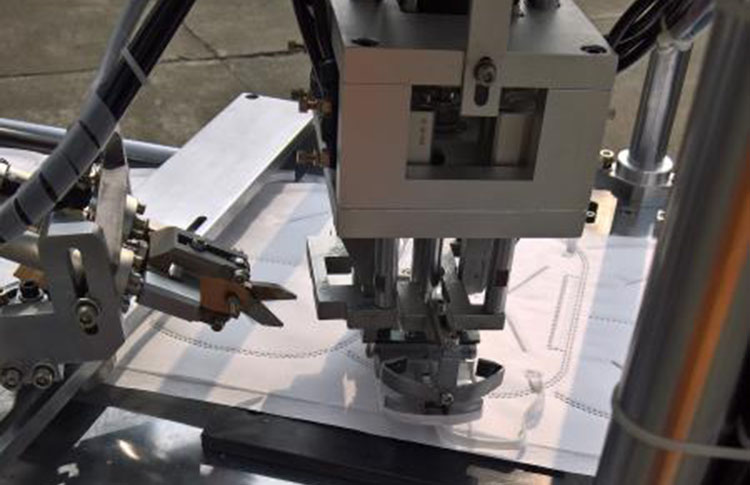

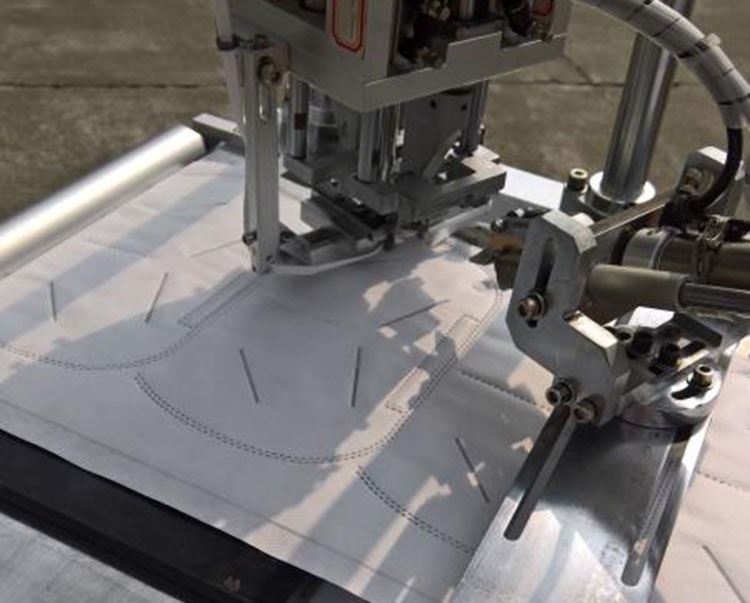

1.3 Automatic KN95 mask machine uses ultrasonic technology, automatic production of 2-6 layers of butterfly masks (such as 3 M company 9001,9002 series masks). Automatic completion of the operation, which includes the process of rolling material feeding, nose beam feeding, mask grain welding, ear belt feeding welding, mask folding welding, mask edge material removal, finished material.

1.4 The equipment produces butterfly masks through servo feeding, positioning system, tension system and each process. In order to meet the market demand, you can simply replace the mold to adapt to a variety of butterfly mask production.

1.5 Customers can specify the shape and appearance of the mask, can be equipped with cloth rectifying device, paste sponge, on-line spray code (laser marking) and other auxiliary agencies.

2. Action principle

2.1 Schematic diagram of equipment structure

Product model | BK-KN0401 |

Machine size | 9700mm * 1400mm * 2100mm |

Drive method | servo motor, stepper motor |

Control panel | human-machine interface (touch screen) and buttons |

Voltage | 220V |

Frequency | 50 \ 60Hz |

Air pressure | 6Kg / c㎡ |

Capacity | 60~90 pcs/min |

Power | 15KW |

Ultrasonic power | 2600W * 4 sets |

Ultrasonic frequency | 15 / 20KHz |

Total weight | 1850KG |